The Attribute Capability worksheet in SuperEasyStats allows you to easily calculate key quality metrics for your product, process, or service. To see how, let’s look at an example. Imagine you are a manufacturer of sunglasses and you are concerned about quality. In order to determine how your manufacturing process is performing, you begin to collect defect data. You know that there are three main components, or elements, that make up the sunglasses:

- Lenses (2 of each)

- Frames (made up of 3 parts)

- Hinges (2 of each)

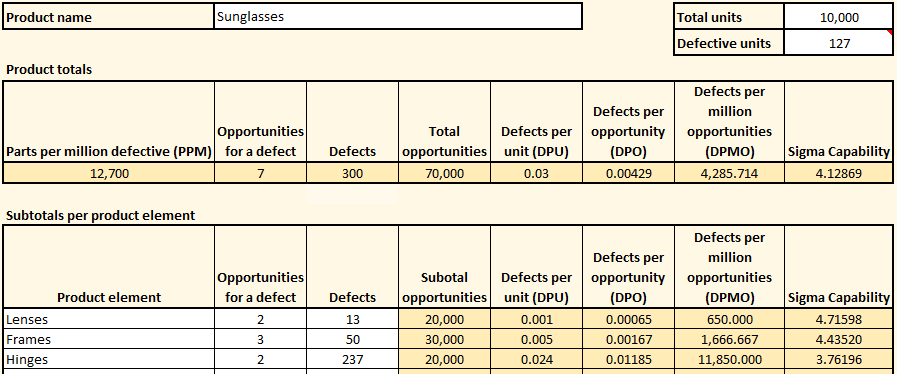

Over the course of a month, your factory manufactures 10,000 pairs of sunglasses and collects the following data:

- In all, 127 pairs of sunglasses were found to have at least one defect (some pairs had more than one defect), and therefore were classified as “defective”

- 13 total lens defects were recorded

- 50 total defects were found in the frames

- 237 hinge defects were recorded

To calculate your quality metrics, click the Attribute Capability button on the SuperEasyStats ribbon and enter the defect data as shown below:

The overall product capability is shown in the “Product Totals” table at the top, and the capability of each element is broken out in the table at the bottom. This allows you to see which element of your product has the largest impact on quality. In this example, Hinges are the major problem with the highest Defects per Unit (DPU) and the lowest Sigma Capability score. But the second biggest problem are the Frames.

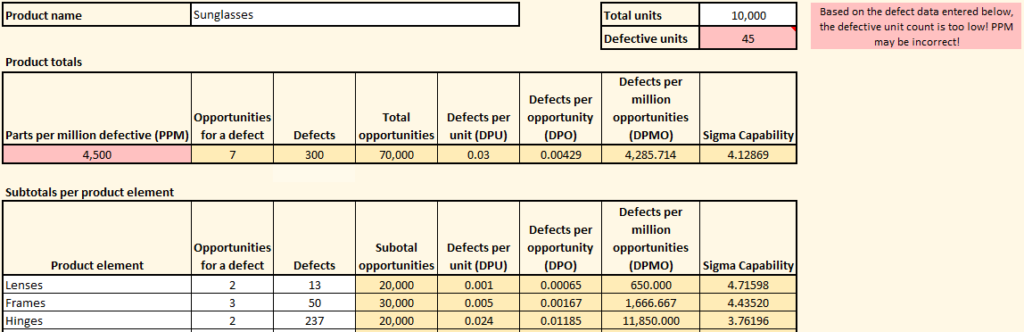

Note that the worksheet does compare the total defective units you enter with the product element data to make sure there are no inconsistencies. For example, if you enter the same product element data as above, but you tell the worksheet that only 45 units are defective (meaning they have at least one defect), the worksheet will alert you that the totals don’t make sense. In this case, 237 hinge defects were found, and there are two hinges per pair of sunglasses, so there must be at minimum 118 defective pairs of sunglasses. In this case, either the number of defective units is incorrect, or the product element data is incorrect.